Overhead Gantry Pick & Place System

Problem:

A high profile medical waste disposal company was in need of an effective method for transferring heavy containers of waste material from a conveyor to an incinerator. Since the waste needed to be moved at a rate of one bin every three minutes, a full-time employee would have been required to manage the task. The need for manual labor to move the large volumes of material for disposal would create an unsafe work environment for employees and would also be highly inefficient.

The customer was considering several options including a conventional conveyor system and an Automated Guided Vehicle System. Multiple complications made a conventional conveyor system difficult and costly, and the AGV System also proved to be too expensive.

Solution:

Lauyans & Company developed a cost-effective Pick & Place System as an alternate to the AGV System. Used in conjunction with conventional conveyor, the pick & place unit provided the ideal solution. Lauyans employed our extensive experience along with our custom design and fabrication capabilities, to provide the waste disposal company the perfect system to meet their needs.

The custom engineered overhead gantry Pick and Place System gets the job done while offering a number of advantages. The Pick and Place System construction is heavy duty with high reliability, and designed to manage 500 lb containers of waste, which are picked from a feed conveyor and emptied to an incinerator. The system was set up, wired and tested in our facility prior to shipment. Upon installation, the precise movements of the robotic functions were programmed into the system.

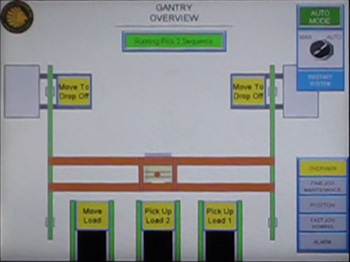

The process starts with a full bin being picked from the feed conveyor and delivered to a dumper. At this point the gantry retracts, and the bin is dumped into the incinerator hopper. The gantry then retrieves the empty bin and places it on a take-away conveyor. The gantry was programmed to pick loads from two separate feed conveyors and load them into two respective incinerators. Gantry motions are performed with Variable Frequency Drives and parameters such as acceleration, deceleration, maximum speed and more, can be adjusted as necessary.

The Pick and Place System controls are designed to provide precise robotic positioning through a system that is accurate and affordable. The control panel features a Human Machine Interface (HMI) with integrated graphics, allowing the operator to see relative position of the gantry in real-time.

Result:

The Lauyans custom engineered overhead gantry Pick and Place System has provided the customer with the advantage of better positioning accuracy, easy programming, and less floor space constraints. Providing full support with installation and set up, Lauyans also provided all the necessary accessories and ancillary material handling equipment to interface with the Pick and Place System.